Part 2- Another Five Reasons to Implement Standard ERP in Poultry Industry

-

October 26, 2016

- Posted by: Admin

- Categories: ERP, Farm management software, News Feeds

No Comments

- October 26, 2016

- Posted by: Admin

- Categories: ERP, Farm management software, News Feeds

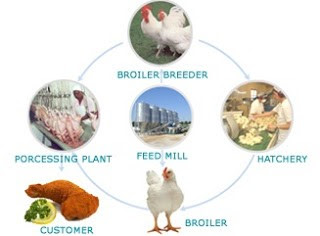

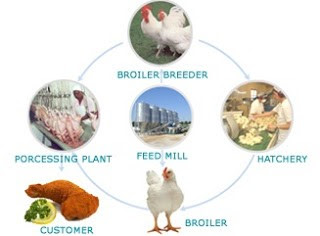

In last blog http://blog.prudencesoftech.com/2016/08/top-five-reasons-to-implement-standard.html, I have promised to come back with a complete edition on the benefits and process of implementing a ERP in the poultry industry. Now in this blog we would go little bit micro to understand the benefits of the standard ERP in Poultry or Hatcheries. So let’s start with the Hatchery Process. This is beginning of the process where eggs laid by the Grand Parents are hatched in the artificial mechanized hatchers to produce parent, Broiler or layer chicks. The prime advantages of using a ERP in the Hatchery are:

- Effective Scheduling: As the ERP system integrates all the processes it gives you an environment where based on the laying cycle and laid eggs, users can schedule the hatching machine effectively.

- Increase in efficiency: Due to advance planning by ERP, organizations can plan the break downs in advance. This opens up lot of opportunity windows for the efficiency improvement with less wastage of eggs. ERP like NAVFARM, helps in defining the machines capacity and availability. Which in turn helps management in taking proactive measures for smooth supply chain.

- Traceability: During chick production it is important to have visibility right from flock number of the grand parent/parent or batch number in case of eggs to the flock number given to the DOC. ERP software helps in maintaining the traceability throughout the value chain. This helps the hatchery owners to establish the root cause for the problems such as cracks, deformities etc in eggs. Moreover you can take corrective action for such problems.

- Cost tracking: Costing is a crucial aspect in the poultry industry. Market is driven by various parameters and management would like to achieve a real costing to manage the market forces. The ERP helps in micro accounting in real time scenario giving a visibility on the daily costing of the Hatchery. This empowers sales managers to drive the better margins.

- Live Inventory: As output of the hatchery is entered in live environment in the ERP, supply manager has the complete visibility in the inventory of DOC including the rejections. In scenario of the multiple hatcheries at multiple location, a centralized view is given by leading ERP such as NAVFARM.

Apart from above points there are more stuff in these ERP and organizations need to evaluate the products with agility, sustainability & scalability. I will be coming with more advantages in continuation to this series. Please feel free to write about above article to marketing@prudencesoftech.com.