Supply Chain Management Importance And Impacts

-

October 21, 2019

- Posted by: Admin

- Categories: NAVOne, supply chain management

No Comments

- October 21, 2019

- Posted by: Admin

- Categories: NAVOne, supply chain management

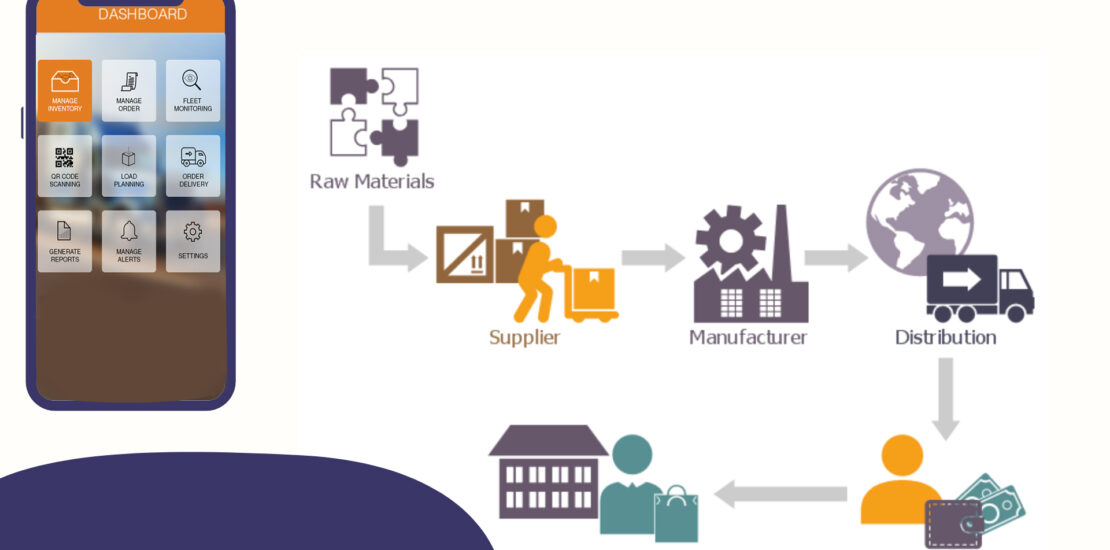

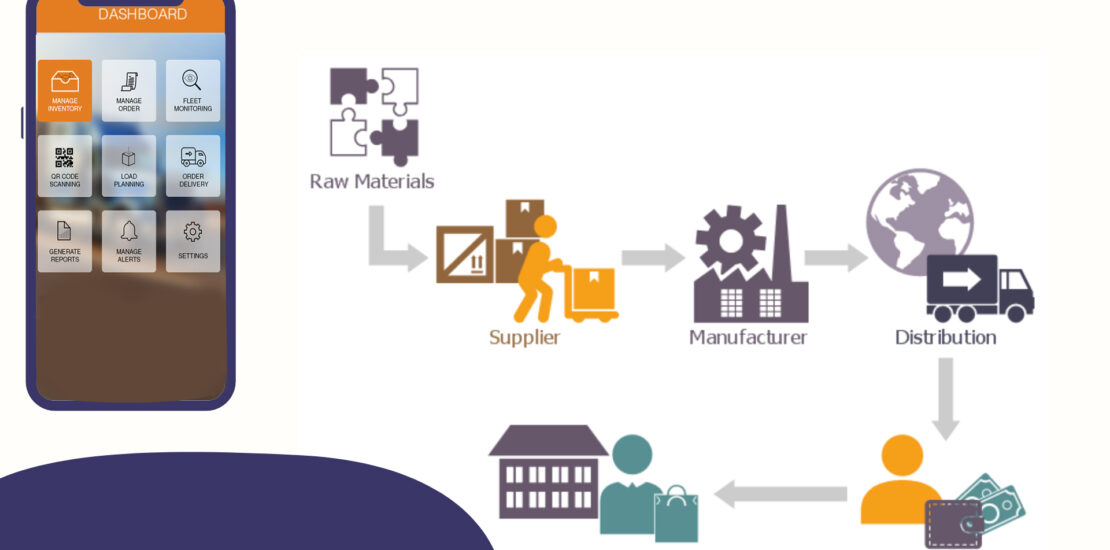

Supply Chain Management (SCM)

In commerce, supply-chain management, the management of the flow of goods and services, involves the movement and storage of raw materials, of work-in-process inventory, and of finished goods from point of origin to point of consumption. SCM (Supply chain management) is the process and activity of sourcing the raw materials or components an enterprise needs to create a product or service and deliver that product

Microsoft Dynamics NAV Supply Chain Management Software handles the flow of the goods and the services. The goal of SCM (Supply chain management) software is to improve supply chain performance. Timely and accurately supply chain information allows manufacturers to make and ship only as much product as can be sold. An effective supply chain system helps both manufacturers and retailers reduce excess inventory. This decreases the cost of producing, shipping, insuring, and storing products that cannot be sold.

MAIN COMPONENTS OF SCM:

- Planning

- Sourcing

- Making

- Delivering

- Returning

- Enabling

1. Planning

Planning is an essential component of SCM as its essential for an enterprise to plan and manage all resources required to meet customer demand for their product or service. They also need to design their supply chains and then determine which metrics to use in order to ensure the supply chains are efficient, effective, deliver value to customers, and meets enterprise goals.

2. Sourcing

Companies must list down the suppliers from which they will accommodate goods and services that are needed for the production of their own product. Now for the contracted Suppliers, supply chain managers use a variety of processes to monitor and manage supplier relationships. Key process includes ordering, receiving, managing inventory, and authorizing supplier payments.

3. Making

One of the major roles of supply chain managers is to conduct & coordinate the activities required to accept raw materials, manufacture the finished product, quality check, packaging for shipping, and schedule for delivery Most enterprises measure the quality, production output, and worker productivity to ensure the enterprise creates products that meet the quality standards.

4. Delivering

Delivering involves customer orders, scheduling delivery, dispatching loads, invoicing customers, and receiving payments. It relies on a fleet of vehicles to ship product to customers. Many organizations outsource the large parts of the delivery process to specialist organizations, particularly if the products require special handling or is to be delivered to a consumer’s home. It can also be specified as logistics department.

5. Returning

The necessity of having a responsive and flexible network for the case of defective, excess, or unwanted products. If the output from the production floor is defective it needs to be reworked or scrapped. If the products is simply unwanted or excess, it needs to be returned to the warehouse for sale.

6. Enabling

Enabling includes some important processes for monitoring information throughout the supply which includes the proceeding: Finance, HR, IT, facilities, portfolio management, product design, sales, and quality assurance.

Importance of Supply Chain Management?

The linked supply chains of manufacturers and retailers have gone very strong over a period of time. Manufacturers with a well-tuned, just-in-time supply chain can automatically restock the retail shelves as products are sold. As collaboration has increased, additional data from supply chain partners has allowed companies to use advanced analytic tool to further improve results. Examples include:

- Forecasting of potential problems before they occur. When the customer’s demand for the product is more than the manufacturer can deliver then, the traditional response has been too short the order. This makes a buyer unimportant and considers the manufacturer’s service as poor. Manufacturers who anticipate the shortage before the buyer is disappointed may be able to offer a substitute product or other incentive to keep the buyer happy.

- Dynamical price optimization. Seasonal product, particularly fashion product, have a limited shelf life. Any that don’t sell by the end of the season is scrapped or sold at deep discounts to empty the warehouse. Airlines, hotels, and other companies with a limited, but perishable products, adjust prices dynamically to meet the demands. While this is more difficult with clothing and other products where the supply can vary widely, similar forecasting techniques can improve the margins.

- Improvisation for allocation of available to promise inventory. Sales forecast, actual orders, and promised delivery of raw materials are basis for the dynamic allocation of the resources and to schedule work as well. Manufacturers are able to confirm a product delivery date when the order is placed, significantly reducing incorrectly filled order.

Some Words About Extended Supply Chain?

The extended Supply chain includes all the entities which have involvement in the production or making of all the goods that will include suppliers of your supplier and customers of your customer.

In case of any problem that encounters in the production of the company the primary task done by the company is to communicate with the primary supplier but in the case of an extended supply chain, the suppliers of the primary supplier are also accounted for the rectification of the problem. As an example, if a popular baseball hat is not available from the manufacturer, the normal reaction of the store manager is to contact the manufacturers. However, if the retailers monitor the extended supply chains, the store manager would know the manufacturers were having trouble getting the brim. If it appears that additional brims will not be available to the manufacturer quickly, the retailers would have time to seek a different supplier.

What are the impacts of globalization on the supply chain?

It is easy to form and maintain relationships across the globe. Globalization has simplified the communications between the business owners and the clients, allowing for better transparency throughout the supply chain processes.

One of the advantages of the global supply chain has been the ability to scatter the patents and manufacturing sites around the globe. This allowed companies to report the profits in countries with low corporate taxes.

How should the supply chains be measured and monitored?

Well-run supply chains are measured in a variety of ways. Metrics help people to focus on the most important activities and improve existing processes. Critical metrics support regulatory compliance, safety, or contractual obligations. Supply chains rely on a variety of metrics. Common metrics include:

- Perfect orders

- Cash to cash cycle time

- Order cycle time

- Fill rate

In reality, there are a lot of supply chain metrics. The art is to find the right ones for your industry and your business.

What impacts do blockchain and smart contracts have on the supply chain?

Blockchain can help companies to realize the digital supply chain by providing a “single version of the truth” for the entire supply chain.

A smart contract automates the “if this happens then do that otherwise do something else” part of traditional contracts. Computer code behaves in a predictable way without suffering from the linguistic nuances of human languages.