6 Needs For Manufacturing ERP software For Electronics

-

January 27, 2020

- Posted by: Shashi Ranjan

- Category: Electronic Manufacturing Industry

No Comments

- January 27, 2020

- Posted by: Shashi Ranjan

- Category: Electronic Manufacturing Industry

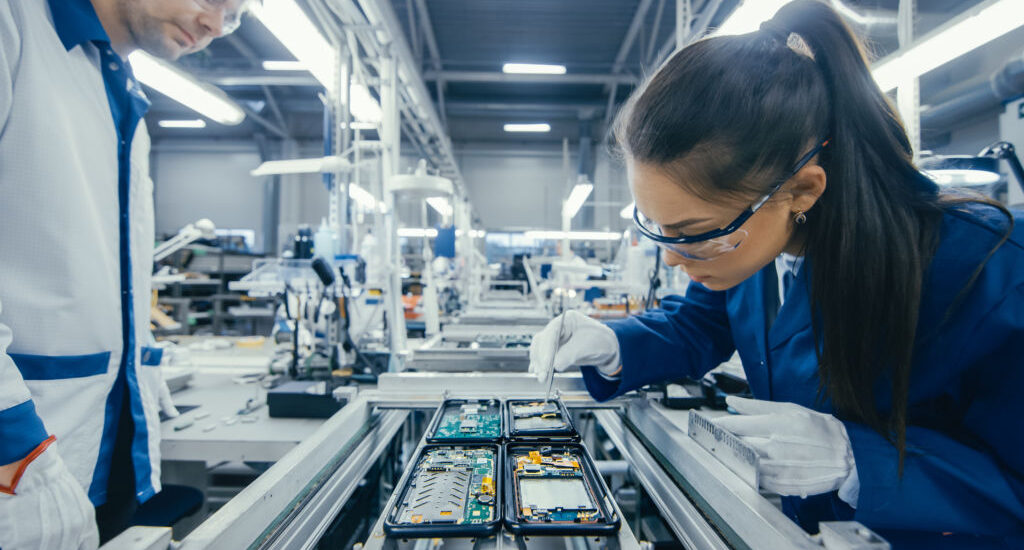

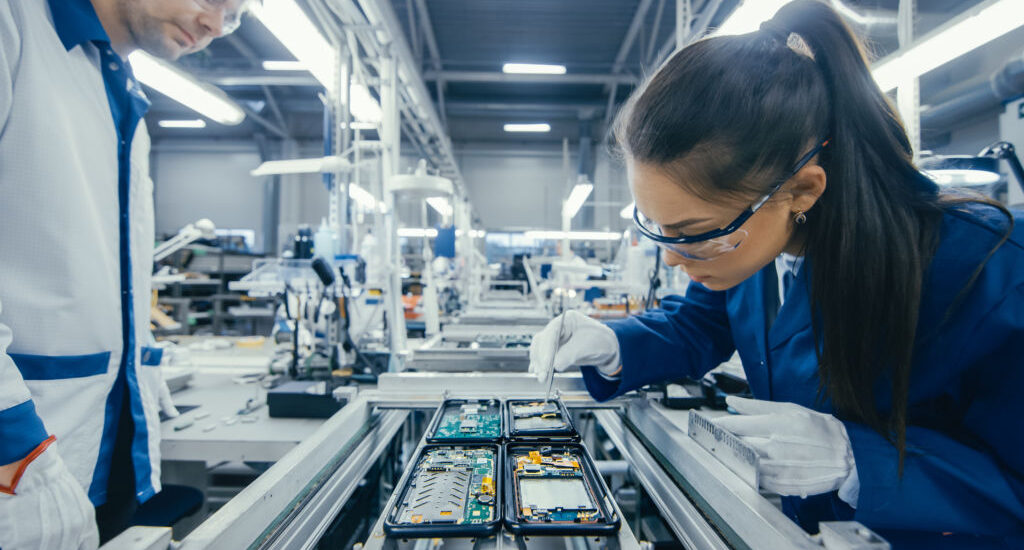

ERP (Enterprise Resources Planning) for electronics manufacturers will most benefit from must deliver operational excellence, safety, speed, and the optimized costs.

These parts will never be turned out of favor with the electronics and the parts manufacturers as they develop the groundbreaking technology, hits the demands precisely and conduct the business with their many vendors and subcontractors.

But with each passing consumer or industry trend, the electronics manufacturers must continuously add to its list of what matters most. We believe, however, the best ERP system or ERP Software for them act as the foundation for instituting and organizing in accordance with the best practices and companies’ individual values.

Electronics manufacturers are usually baffled with the aim of the cutthroat competition, traceability, product life cycles, supply chain management, enterprise-wide visibility, warranty and constantly evolving statutory and regulatory compliance. With already existing the MRP, CRM in this list, these manufacturers also strive to meet the ever-growing demands for creating the innovative products and at the same time uplifting the efficiency and maintaining supreme quality. Despite present day’s cutting-edge, advanced ERP software for the electronics industry work excellently to help businesses address and meet the potential challenges in an efficient and faster way.

Here, The 6 Needs For Manufacturing ERP software For Electronics

1. Automation

ERP System automates the vendor list, material billing, orders, and the other basic manufacturing processes to help the curtail inefficiencies in data handling and errors in production. This plays a prime role in improving the quality of manufactured electronics.

2. Management of the intricate supply chains

It is much much and much important for an electronics manufacturer to communicate in the real-time via web-based industrial manufacturing Cloud ERP software. This empowers the company to share the information with all its suppliers from a single platform hence, shunning the use of phone calls, email, fax, etc, which is tedious and the time-consuming. The crux here is to going paperless and engaging in real-time communication through a single ERP solution (Enterprise Resources Planning Solution) to boost the operational excellence, productivity, and the visibility.

3. Track and enhance quality

Tracking of defects and weaker areas in the production process is of the optimal requirement for the electronics manufacturer. ERP for electronics manufacturers tracks all the fragile areas and defects them automatically paving the way for the real-time and seamless data flow across the organisation.

4. Promote lean management

Electronics manufacturers should integrate lean tools for optimising the supply chains. Hence, ERP systems for manufacturing companies must help businesses to obtain seamless data flow that is demand-centric and accurate. The system is expected to automate the internal communication, production tracking, materials traceability, and the inventory management.

5. Improve Traceability

An industrial manufacturing ERP software should automatically track the product codes and also the availability against the raised orders. This calls for having a feature that boosts the traceability of the diverse products manufactured.

6. Improve visibility

Electronics manufacturers should have an ERP system that offers the real-time visibility all throughout the organisation. This calls for intuitive tracking of the machines, supply chain, production processes, costs, materials, etc. In other words, sales professionals and the managers should gain quick access to the key metrics and KPIs (Key Performance Indicator) related to the sales, costs, materials, order, supply, production, etc. to help them make informed decisions and anticipate better.

Prudence Technology helps you in implement the right ERP system for your electronic manufacturing organization to run your business in your way. We are the partner of Microsft and Oracle and we do provide the ERP system that easily integrates with your purchasing, sales and billing, inventory, vendor management, product management, and financial reporting processes on a single platform and gain insight into day-to-day business operations in the real-time.