ERP for Slaughterhouse

ERP for Slaughterhouse

ERP for Slaughterhouse (Abattoir Operations)

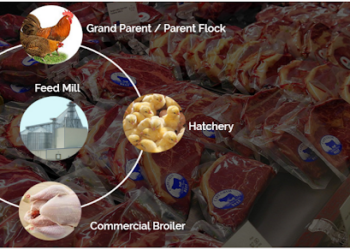

The global rise in meat consumption, coupled with the scarcity of organic food and the pressing concern of climate change, has underscored the importance of maintaining top-notch food processing units. In this context, the necessity of implementing an ERP for slaughterhouse (also known as ERP for abattoir management) operations becomes evident. These ERP systems play a pivotal role in standardizing business operations, ensuring a process-oriented approach, and addressing the depletion of natural resources.

As customer expectations evolve, their prior exceptional encounters set the benchmark for future ones. Technology continuously heightens this standard, fuelled by competitive marketing. Remarkably, statistics emphasize that customers are willing to invest more for superior experiences, yet many feel companies are falling short. This holds true even for an ERP for Aqua Tuna Processor, where elevating operational efficiency aligns with enhanced customer satisfaction.

FAQs

The primary activities and processes involved in a slaughterhouse include animal reception and inspection, stunning, slaughtering, carcass dressing, meat processing, quality control, and packaging for distribution.

- Maintaining stock levels

- Material Traceability

- Managing expenses

The key advantages of implementing an ERP system in a slaughtering business include:

- Improved inventory management

- Enhanced traceability

- Streamlined production processes.

- Better compliance with safety and regulatory standards.

MSD 365 BC includes.

- Advanced quality management tools

- Allow real-time monitoring of production,

- Tracking of raw materials,

- Conducting quality checks, and

- Maintaining detailed records for easy traceability.

By following industry-specific regulations and safety standards, Prudence ensures the slaughterhouse operates smoothly and safely.

- While transferring a live batch

- Batch Number

- Gross Weight

- Cost of Production

- While Inspection

- Weigh Bridge Integrated value

- Catch Weight & Dead Weight Management

- Overhead Cost like transportation

- While Production

- Multistage Inventory

- Yield Control: Estimated vs Actual retrieval

- Capacity Planning

- Shelf-life Management

- Maintenance Schedules

- While Despatch

- Lot Number for Traceability

- QR Code Tagging

- Quality Assurance

- Nutritional Value

“The results were clear, professional, and persuasive, and the investors and advisors who have seen the materials loved them. They know what investors want!”

Submit a Business Enquiry

Connect with Us!

Please fill in your details below, and our

advisors will give you a call.